What is 3D Printing?

3D printing (also called additive manufacturing) is a process that creates physical objects from digital designs by adding material layer by layer.

Think of it like this: instead of carving a sculpture from a block of wood (removing material), 3D printing builds an object from the ground up by stacking thin layers on top of each other—like building with LEGO bricks, but much more precise.

How Does 3D Printing Work?

The process is surprisingly straightforward:

1. Create or Find a 3D Design

First, you need a digital 3D model—a computer file that describes the shape of your object. You can:

- Design it yourself using 3D modeling software (like Fusion 360, Blender, or Tinkercad)

- Download ready-made designs from online libraries

- Hire a designer to create it for you

- 3D scan an existing object

2. Prepare the File

The 3D model is converted into instructions (called G-code) that tells the printer exactly where to place material, layer by layer.

3. Print the Object

The 3D printer follows these instructions, depositing material layer by layer until the object is complete. Depending on the size and complexity, this can take anywhere from 30 minutes to several days.

4. Finishing (Optional)

After printing, you may need to:

- Remove support structures

- Sand rough surfaces

- Paint or apply finishing touches

Common Types of 3D Printing

There are several 3D printing technologies, but these are the most common:

FDM (Fused Deposition Modeling)

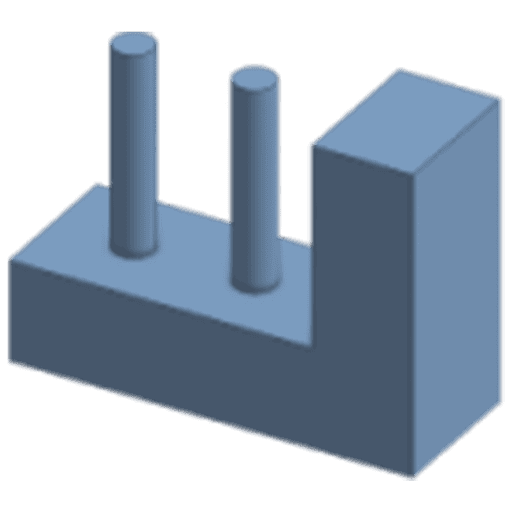

How it works: Melts plastic filament and deposits it layer by layer, like a hot glue gun that draws in 3D.

Best for: Prototypes, functional parts, architectural models, everyday objects

Materials: PLA (biodegradable plastic), ABS (strong plastic), PETG (flexible and durable), TPU (rubber-like flexibility)

Advantages: Affordable, versatile, wide range of materials

SLA (Stereolithography)

How it works: Uses UV light to cure liquid resin into solid objects, one layer at a time.

Best for: Highly detailed models, jewelry, dental applications, smooth finishes

Materials: Various resins (standard, tough, flexible, castable)

Advantages: Extremely high detail and smooth surface finish

SLS (Selective Laser Sintering)

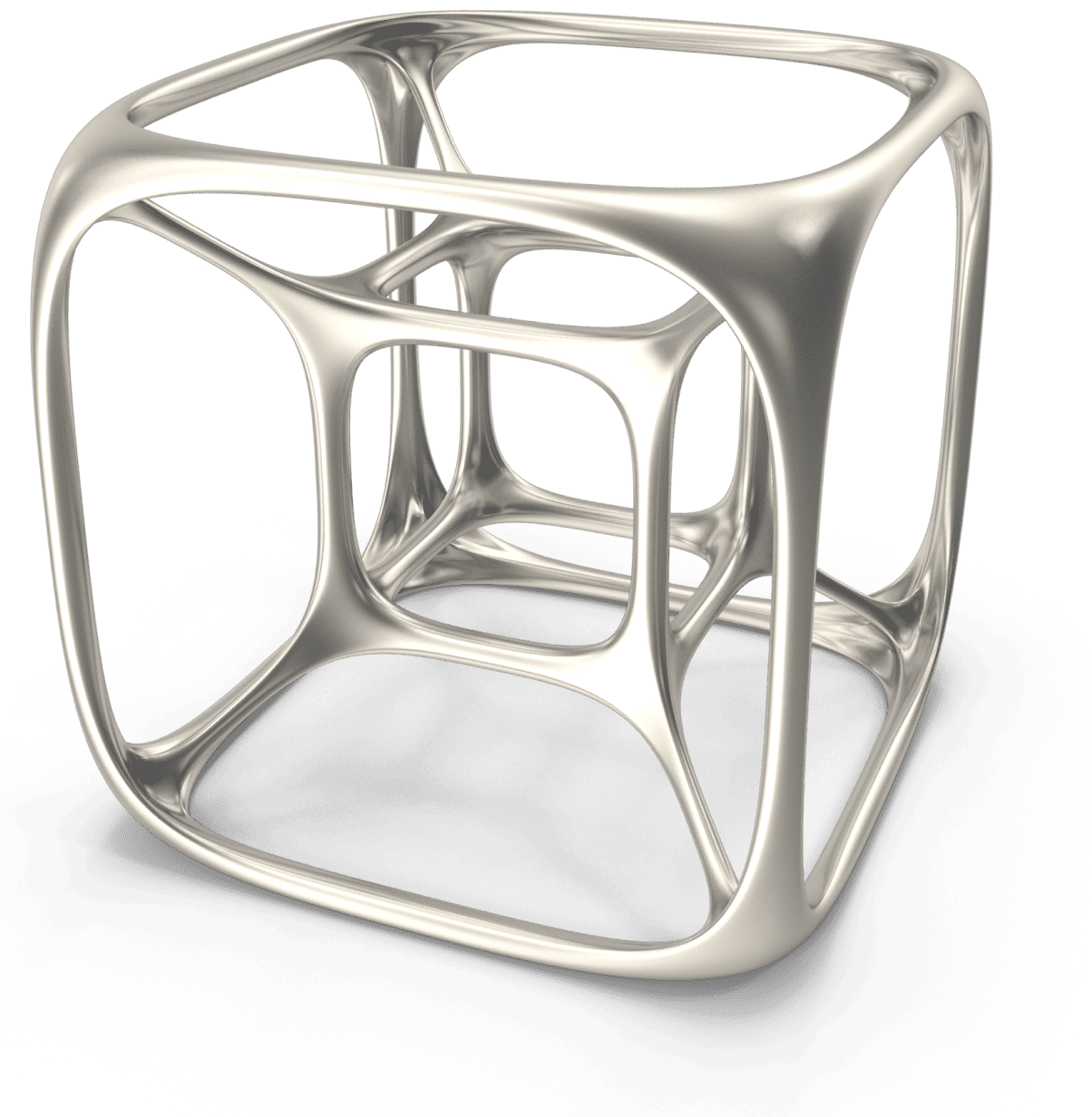

How it works: Uses a laser to fuse powdered material into solid structures.

Best for: Functional end-use parts, complex geometries, industrial applications

Materials: Nylon, metals, ceramics

Advantages: Very strong parts, no support structures needed

What Can You Make with 3D Printing?

The applications are nearly endless! Here are some common uses:

Product Design & Prototyping

- Test product designs quickly and cheaply before manufacturing

- Iterate multiple versions in days instead of weeks

- Show clients physical models instead of just drawings

Manufacturing & Production

- Create custom parts and tools

- Produce small batches without expensive molds

- Make replacement parts on-demand

Architecture & Construction

- Build detailed scale models of buildings

- Create presentation models for clients

- Prototype design concepts

Healthcare & Medical

- Custom prosthetics and orthotics

- Dental appliances and models

- Surgical planning models

Education

- Teaching aids and visual learning tools

- Science and engineering projects

- Hands-on STEM education

Art & Design

- Sculptures and art installations

- Custom jewelry

- Fashion accessories

- Home décor items

Advantages of 3D Printing

1. Speed

Create prototypes or parts in hours or days instead of weeks or months with traditional manufacturing.

2. Cost-Effective for Small Quantities

No expensive molds or tooling required. Perfect for one-off custom parts or small production runs.

3. Design Freedom

Create complex shapes and internal structures that are impossible or expensive with traditional manufacturing.

4. Customization

Every item can be different without additional cost. Perfect for personalized products.

5. Less Waste

Only use the material you need. Traditional manufacturing (like CNC machining) cuts away excess material.

6. No Minimum Orders

Print one piece or one thousand—the choice is yours.